Bio pharmaceutical production waste water usually contains pathogenic microorganism, such as pathogenic bacteria and viruses, which have serious harmfulness. It is necessary to be sterilized to kill pathogens before being discharged to sewage treatment system.

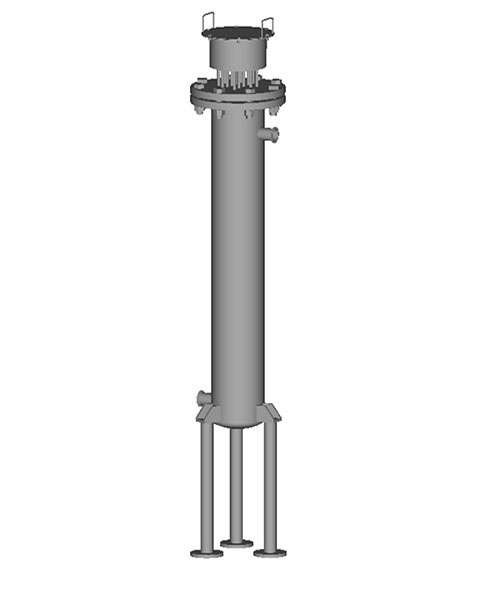

Based on the above, Shanghai Ritai has developed an inactivation system for biological waste water. This system sterilizes through continuous stable high temperature which makes the thallus degenerated or inactivates the coagulase; On the other hand, the viruses are inactivated by bond fission because the DNA and RNA absorbs heat under high temperature.

This system adopts batch treatment. It is equipped with a collecting tank and two or more than two inactivation tanks. Through intermittent operation, it ensures energy conservation, environment protection and high reliability. Furthermore, the whole system adopts intelligent control, which realizes unattended operation and full automatic operation. And it has achieved remarkable results in practical projects.

Please visit Alibaba: https://ritaichina.en.alibaba.com for more technical details!