Applications

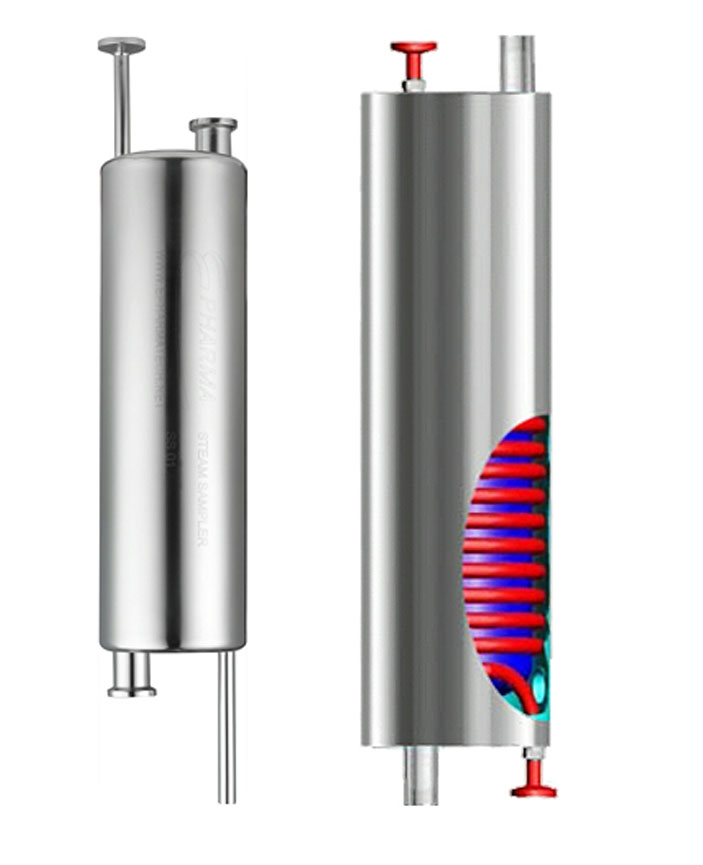

It is a high quality DTS shell & tube heat exchanger especially meets the high hygienic demands of the pharmaceutical industry. The heat exchanger was designed to work in the highest hygienic conditions in applications such as water-for-injection (WFI), Purified Water (PW), and heating/cooling of pharmaceutical products.

Working principle

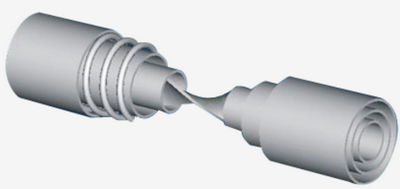

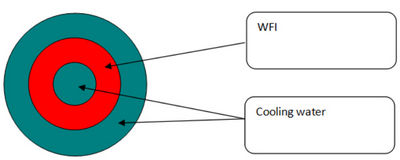

The product media flows through a bundle of seamless, polished tubes. The service media flows outside the tubes in a cross flow. At the end, the tubes are fastened by two tube-sheets acting as leakage indicators, preventing cross contamination between the product and the service media.

The heat exchanger can be installed horizontally or vertically depending on the duty or space. Thermal fatigue caused by large temperature changes is managed by expansion connection in straight units.

Features and Benefits

• 100% of import Seamless tubes.

• Double tube-sheets to protect against service media leaking into the product.

• Completely drainable on product side and easy to clean.

• No dead point in the tubes.

• No risk of cross contamination.

• Designed according to FDA and cGMP requirements.

• Flexibility or standard in design.

• A high quality documentation package as standard.

Please visit Alibaba: https://ritaichina.en.alibaba.com for more technical details!